Optimized Mechanics and Control System: More Professional, Stable, More Accurate, and Easier to Control

Optimized Mechanics and Control System: More Professional, Stable, More Accurate, and Easier to Control

1, More Professional

→ USA KINO uniquely has deeply researched in precision positioning stage and applied it into interfacial chemistry analytical system;

→ More professional knowledge and abilities:

Instruments from USA KINO have obvious advantages because our more professional knowledge, R&D capacity and product quality are comparable to others in the industry from US and European. We guarantee profession, stable and convenience in mechanical control.

2, Integral design with more compact and optimized

→ Optimized integral design:

The mechanics are optimized by our practiced engineer in terms of precision optical vision system, which effectively improves mechanical compatibility without any structures complicated or appearance uglified.

→ Better coordinated mechanics:

Uniquely-designed mechanism of up to 10 axis control (6-axis linear adjustments +1 rotation adjustment + 3 horizontal adjustments), to coordinate the operation of sample stage, lens, camera, dosing system and vision system.

→ Integrate designed instrument with mainframe made of high-grade aviation aluminum guarantees its handiness and fastness.

3, More accurate, stable and diversified mechanics and control system

→ More stable operation stage and control system of sample stage

- State of the art linear guide and precision screw enable larger operating range, more stable travel and more accurate drop positioning;

- Precision positioning stages used in hardware control system, with resolution up to 0.01mm by manual and 0.007μm by software control respectively.

- Crossed-roller bearing and precision vertical travel positioner used micrometer in sample stage lift control effectively ensures level control, base line detection of solid sample and load capacity (approx.6kg) of sample stage.

→ Focal distance and positioning control of droplet with easier operation and more precision

- Precision positioning stage with micrometer and crossed-roller bearing guarantee smooth moving, as well as more accurate positioning control and focus distance adjustment with fewer backlashes.

- Unique mechanism of fixed focal distance and high-precision adjustable positioning stage, with easier and more accurate focal distance obtaining, clearer and sharper image capture.

→ More stable and accurate drop transferring

- Flexible focus control system and micro distance of needles moving (about 0.01mm) makes more accurate and easier operation of transferring drops, especially for super-hydrophobic biomimetic material surface test.

- Small droplet within 5uL can be easily transferred with our ultra-fine needle or PTFE needle for super-hydrophobic surface.

→ More professional control mechanics for dynamic contact angle (roll off angle)

- Professional design of rotary positioning stage without backlash guarantees stable operation and accurate angle control with its accuracy of up to 0.1 ° by manual and 0.01° by software control as well as resolution of up to 0.0001°.

- Integral rotation system controlled by rotary positioning stage, enabling sample stage to rotate with lens in order to hold drop image in field of view during capture process. The unique design makes accurate analysis of roll off contact angle possible without hard operation and bad precision when rolling the entire instrument, as well as avoiding drop disappearing from the field of view when partially rotating.

- Besides, just a simple switch can enable of sample stage rotating only. (Manual and electronic tilting base for option).

→ Mechanics with accurate level and lens tilted angle adjustment

- System with four level adjustment units:

- Except one complete machine level adjustment via quadrupled tuning knob and one precision tilting angle adjustment of lens and camera via 1 axis tilt platform stage with micrometer, we provide one multi-axis tilt platform with micrometer to adjust the level of sample stage and one zero-backlash rotary stage to roll the sample stage in addition. All these guarantee the accuracy of base line detection and the measurement of roll-off contact angle.

- Micrometer used in our multi-axis tilt platform can effectively improve accuracy of adjustment angle of level;

C60 uses high-precision one-axis tilt platform to adjust tilted angles of lens and light source, which improved adjustment accuracy of angle via high-resolution micrometer.

- Adjustment both by hardware and software with better base line detection.

The level adjusting mechanism, illumination-adjustable LED cold light source as well as CAST 3.0 software system provide you strong assurance of better base lines detection, and more convenient for measuring roll-off angle and advancing / receding contact angle.

4, Control system-easy, convenient, human-oriented

→ The adoption of stepping motor in auto control system enables higher accurate and more stable operation;

→ The adoption of communication port-USB2.0 in system of mechanical moving control and camera ensures better compatibility.

Optical Vision System-Clearer, Higher Speed and More Professional

Optical Vision System-Clearer, Higher Speed and More Professional

1, Unique high-precision telecentric lens

→ Continuous 6.5-fold zoom lens, magnification range: 0.75X-4.5X

→ Clearer and sharper drop profile and smaller diameter of spot size

→ Larger depth of field, low TV distortion, high resolution

→ Image magnification does not change as object distance varies

→ Low distortion: <0.01% (Full screen)

→ Viewing and displaying the entire drop shape from the same prospective angle with no projection for vertical imaging

.jpg)

|

.jpg)

|

|

Contour lens

|

General industrial lens

|

2, Unique parallel background light

→ Clearer and sharper drop profile

→ Better for shape edge detection with a sub-pixel accuracy

→ More accurate geometric dimension of drop shape

→ Continuously adjustable lumination LED cold background light source, guaranteeing longer life and avoiding volatilization of little droplet caused by extra heat in measuring process

→ More homogeneous background light and clearer imaging

→ Short wavelength light is especially suitable for imaging of liquid drop

3, High definition and higher speed vision imaging system

→ High speed camera with speed of 87FPS ( WVGA format)-340FPS(GIF format);

→ UV filter technology is better for improving sharpness of imaging for drop shape;

→ Optional with various cameras: HD, high-speed (10, 000FPS) and more

→ USB2.0 as standard configuration effectively enhances compatibility of integral system;

.jpg)

Absorption effect of sanitary pads images serial used high speed camera (750FPS)

Dosing System of Higher Accuracy and More Convenient to Control

Dosing System of Higher Accuracy and More Convenient to Control

1, Direct syringe pump with higher precision and more accurate quantity

→ Professional high-precision syringe pump with accuracy of droplet control down to 0.002uL, which can be applied to high-precision repetitive sample dosing.

→ Direct-type design facilitates cleaning and changing of sample tube without cross contamination;

→ Precision screw and linear guide enable higher accuracy of positioning control;

→ Communication port-USB2.0 guarantees better compatibility.

2, Optional with diversified dosing system

→ Syringe pump with tee-junction dosing system is optional available and it can be easily upgraded to multi-channel pump (up to 8 channels).

→ Dosing system of up to 8 channels and 8 needles is specially designed for dosing of multiple liquids in measurement of surface free energy.

→ Ultra micro volume dosing system of 10nL, 5pL, 15pL, 800pL and more are optional available for measurement of single fiber contact angle and contact angle of um size sample in industries of semiconductor, chip and semi-electronic.

3, Various syringes and needles to meet different requirements

→ Different volume syringes such as 25μL,100μL,500μL,1000μL……), different material (plastic, glass) and different brands (KINO, Hamilton)

→ Needles of different size (10-34#) , different materials (stainless, PTFE , PP) and needles for special use like curved needle for captive bubble method.

They can be used for measurement of normal contact angle, and also for dosing and drop transferring in measurement of super-hydrophobic sample and high-viscosity sample.

World Leading, More Powerful, Automatic and Ergonomic Analytical Software- CAST®3.0

World Leading, More Powerful, Automatic and Ergonomic Analytical Software- CAST®3.0

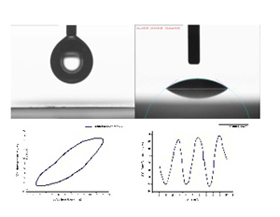

1, RealDropTM method based on ADSA

→ Wider fields of applications

It can be used to measure surface / interface tension and contact angle by sessile drop and captive bubble as well as surface / interface tension of liquid-gas / liquid-liquid by pendant drop.

→ Higher measurement accuracy

RealDropTM method is quite different from select plane based Young-Laplace equation fitting method, which adopts AFLI and 4th generation RealDropTM technology and achieves higher measurement accuracy without any experience calibration value.

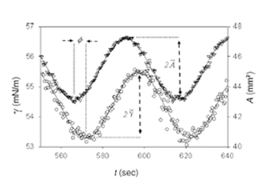

→ Unique interface tension measuring system of liquid-gas / liquid-liquid with Young-Laplace equation fitting method based on Bashford-Adams table, ADSATM(Runge-Kutta arithmetic and RealdropTM method) and capillary pressure method. It can be used for surface tension measurement of medium-high viscosity sample, dynamic surface / interface tension measurement of surfactant, and oscillating drop measurement.

2, Powerful analytical functions

→ Six drop shape states for analysis: sessile drop (liquid/gas, liquid/liquid/gas), pendant drop, captive drop, tilted plate and oscillated drop

→ Seven methods to calculate contact angle and nearly 20 kinds of curve-fitting technologies:

- Exclusive methods of θ/2, circle fitting, ellipse fitting, RealDropTM, spline curve-fitting, Young-Laplace equation fitting, curve ruler (tangent method);

- Dynamic / static contact angle measurement

- 20 exclusive curve ruler methods, such as circle, spline, Gaussian and Power, enable you to analyse:

●Advancing/receding contact angles

○Irregular angles

→ Twelve surface free energy calculating models, providing you more options to estimate surface free energy and its distributions.

Exclusively provided 12 methods for estimating surface free energy, e.g. Equation of State (Neumann et al.), Good-Girifalco, Owen-Wendt-Rabel, Simple Fowkes, Extended Fowkes, WU method 1-2, Schultz method 1-2, Acid-base (Van OSS & Good), Jhu, and Zizman Plot (critical surface tension) method, can be used to measure free energy and its distribution (dispersive force, polar force and hydrogen bond value, and Lewis acid-base, etc.) of low / high energy solid surface.

→ Unique technology of wetting behavior analysis (WBA / wetting envelopes).

A 2D map of wetting envelope can be constructed by using the components of surface free energy and corresponding method (such as OWEN), and a plot produces to show how wettability occurs. It is another way of understanding contact angle, hence degree of wetting, arise from an understanding of the force existing in the material and between the materials.

.jpg)

Wetting behavior analysis of low-energy solid material

→ Unique video recording function. Measurement process can be recorded into AVI format for later use.

→ Rod, thread and tilted plate method based interface tension and contact angle measurement for analysis of contact angle of single fiber. (Need to choose and buy related accessories).

3, Automatic, human-oriented and high-precision function design

→ Standardized windows technology based video capture technology with better compatibility.

The standardized design of video capture method with windows multimedia technology enables the compatible of various contact angle meters around the world. Just enjoy the convenience brought by CAST ®3.0.

→ Real-time images analysis

It can be used to automatically analyze time-dependent interface tension/contact angle/volume/wetting line, and image is one-to-one correspondence with data for you to conveniently analyze measured value at any time.

→ Auto base line detection and curved surface base line correction

Exclusive curve base line based circle- fitting or curve-fitting of unilateral arbitrary curve shapes with easier operation and achieving more accurate result.

→ Dual-Software Triggering Technology for analysis of complicated dynamic/static contact angles.

Unique dual-software triggering technology of CAST®3.0 can not only be applied to measure static contact angle but also advancing / receding contact angle, roll off angle, time-dependent (standard speed is 25 FPS, and camera with higher speed are optional) contact angle and zero-time contact angle of ultra-water absorption material ( e.g. powder, fiber, paper, and artificial periosteum). It is applied more extensively with better measured result.

→ More comfortable software user interface:

(1) New-generation wizard UI. Our software will implement measuring contact angle, surface free energy automatically at the touch of a finger according to wizard UI. Besides, with our 140-page user manual, you can operate the instrument easily without any professional training.

(2) Unicode based software interface. Its English user interface can easily be changed to other language (such as Simplified-Chinese), and makes it more convenient to operate.

→ Fully automatic analysis of contact angle, adhesive work and surface free energy:

(1) Fully automatic. Just press ”Measure”, images capture, contact angles calculation, data storage and real-time display measured value will be done without manual intervention.

(2) Manual modification function. Double-click ”Modify”, you can modify measured value by captured image, and software saves the record of operation trace conveniently to avoid errors of automatic measured values.

(3) Real-time graph. Left/right contact angle, average contact angle, adhesive work, surface free energy based on equation of state method can be real-time displayed without extra calculation.

4, Powerful database management

→ Most comprehensive liquid database

We provide 300 kinds of liquid with 800 data values of liquid surface tension and its contributions as reference data or for faster analysis of surface free energy of solid.

→ Powerful database management for convenient storage, query, and exporting data:

√ Access database technology provides you more powerful functions

√ Real-time saving and indexing of measured values

√ One-to-one correspondence between measured data and image; corresponding drop image is automatically displayed when the data is selected

√ Historical data query

√ Modification of historical data

√ Importing and backup of historical data

√ Database compression

√ Measured data exportable.

→ All measured data can be exported into Excel file and image file into BMP file, which can be easily imported into scientific article and testing report.

Various and Fully Functional Software Modules for Drop Shape Based Interface Chemistry Analysis

Various and Fully Functional Software Modules for Drop Shape Based Interface Chemistry Analysis

CAST®3.0 consists of different software modules

→ SM01: contact angle measurement module (ADSA-SD)

SM01 is main module of CAST®3.0 with functions of image capture, image recognition and processing with a sub-pixel accuracy, curve fitting, database management, which can be used to measure surface / interface tension and contact angle by sessile drop and captive bubble as well as advancing / receding contact angle / roll off angle / equilibrium contact angle / thermodynamics contact angle.

→ SM02: measurement of surface/interface tension by pendant drop(ADSA-PD)

Young-Laplace equation fitting based ADSA module for measurement of surface / interface tension; fitting methods: Bashford-Adams (BA) table and RealdropTM;

Optional with Select plane method based Young-Laplace fitting technology (Andreas-Princeton, Springer, Huh, Lin, Hansen); measurement of surface tension (SE) of liquid and its contributions (dispersive force, polar force, hydrogen bond value and more) in terms of liquid-liquid interface tension.

→ SM03: analysis of surface free energy and wettability (SFE&WBA)

SM03 is designed to evaluate surface free energy and analyze wetting behavior and wetting envelopes of solid

→ SM04: ultra-low interface tension measurement by constrained sessile drop method (ADSA-CSD)

SM04 can be used to analyze low interface tension and its time-dependent properties used constrained sessile drop that formed in a sharp edge needle.

→ SM05: contact angle analytical module of single fiber (ADSA-SF)

SM05 is used to measure contact angle of fiber for covered drop via max Length-Height method.

→ SM06: interfacial rheology analytical module (ADSA-IR)

SM06 is used to analyze interfacial rheology, surface elasticity, relaxation study, hydrostatic pressure, etc.

→ SM07: electro wetting analytical module (ADSA-E)

SM07 is used to measure contact angle dependend voltage changing in electric field

→ SM08: contact angle measurement by top view (ADSA-D)

SM08 is used to measure contact angle for large sample.

→ SM09: analytical module of liquid profile without apex (ADSA-NA)

SM09 can be used to measure asymmetry contact angle and advancing / receding contact angle using Young-Laplace equation fitting method .

→ SM10: bounce energy analytical module of dynamic drops (ADSA-HS)

SM10 can be used to analyse dynamic energy of drop adhesive / un-adhesive on solid surface.

Bouncing of drops on super-hydrophobic lotus leaf captured by high-speed camera of 750FPS

→ SM11: ADSA-LMP / Lamella & menisci profile analysis by Young-Laplace equation fitting method, etc.

Lamella & menisci curves based on Young-Laplace equation fitting method can be tailored to measure interface tension or other interface chemistry properties.

Well-equipped Accessories

Well-equipped Accessories

1, Environmental chambers -pressure, temperature, humidity dependence

→ Temperature chamber including:

(1) Solid sample temperature control,

(2) Temperature control of test liquid;

(1) and (2) are two temperature control systems for controlling temperature of liquid samples and solid samples respectively. Clients can purchase either or both of them.

.jpg)

→ The following environmental chambers for solid samples are optional:

(1) Sample chamber

- Connect to water circulator control temperature of sample

- Temperature range: -40-150℃

- Resolution: 0.01℃

(2) Peltier semiconductor heating and refrigerating chamber: Temperature range:5-85℃, resolution: 0.5℃;

(3) Special temperature heating chamber: Any special requirements for temperature control, such as 200℃ and 400℃, please contact us for confirmation.

It is recommended to use water circulator for liquid temperature control.

→ Contact angle measurement in high-temperature of 1400℃, 1700℃, 1800℃, and 2000℃ can be realized; a down payment is required for custom maded.

→ Contact angle measurement in vacuum environment or different gas environments can be realized; a down payment is required for custom made.

→ Sample chamber: Samples can be kept completely stable and free from effect of temperature and light dazzling; a down payment is required for custom made.

→ Sample chamber for measurement of high-temperature interface tension:

Method of pendent drop or sessile drop is used for measuring interface tension between melted solid materials and air; a down payment is required for custom made.

→ Sample chamber of high pressure and high temperature: optional with 10MPa,35MPa and 70Mpa, heating range of 200℃ and observation window of sapphire;

Thermo-stating sample chamber: control of humidity and temperature.

2, Full series sample stages, holders and sample vessels

→ Sample stage for wafer : 6’(φ150mm), 8’ (φ200mm), 12’ (φ300mm)

→ Sample stage for PCB: 100*250mm

→ Sample stage for electro wetting: Measuring contact angle depended voltage changing in electric field (ADSA-E module should be purchased)

→ Various sample holders: For fiber, thin film, paper, powder sample chamber, slot for fixing hand or leg, holder for fixing cylinder; specific holder can be custom made.

→ Sample vessel made of optical quartz glass with size of 100*120*36, 46*36*47, 60*32 and more, for analysis of liquid-fluid-gas interface tension and interface tension via captive bubble method.

.jpg)

3, Full series syringes and needles

→ Full set of high-precision micro syringes: 25μL, 100μL, 500μL, and 1000μL, etc.

→ Full set of needles: PTFE, stainless steel (various OD such as 2mm, 1mm, 0.5mm,0.3mm, 0.23mm,etc. ), plastic, and curved needles for captive drop method etc.

→ Dosing control system of different specifications

Syringe pump, peristaltic pump, dosing system of microliter/ nanoliter / picoliter (min.5pL)

.jpg)

4, Oscillating drop module (ODM)/ expanding drop module(EDM)

→ The leading-edge high-frequency oscillator and oscillation control system designed by USA KINO enables higher control precision and more flexible control mode. Oscillator with different oscillation frequencies and amplitudes is available at your option.

|

No.

|

Amplitude

|

Max. Frequency

|

|

1

|

2uL

|

100Hz

|

|

2

|

10uL

|

100Hz

|

|

3

|

10uL

|

60Hz

|

|

4

|

20uL

|

60Hz

|

→ Optional sample dosing syringe: 0.5μL, 1μL, 5μL, 15μL, 100μL, 500μL and 1,000μL etc.

→ The oscillation waveforms cover sine wave, cosine wave, triangular wave, linear wave and saw tooth wave without attenuation or distortion when below 2K Hz.

5, Calibration standard set for different methods

Calibration standard set for circle fitting, Young-Laplace fitting (sessile drop, pendant drop) with metrological certification is provided.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)